36 Colors

12 Materials

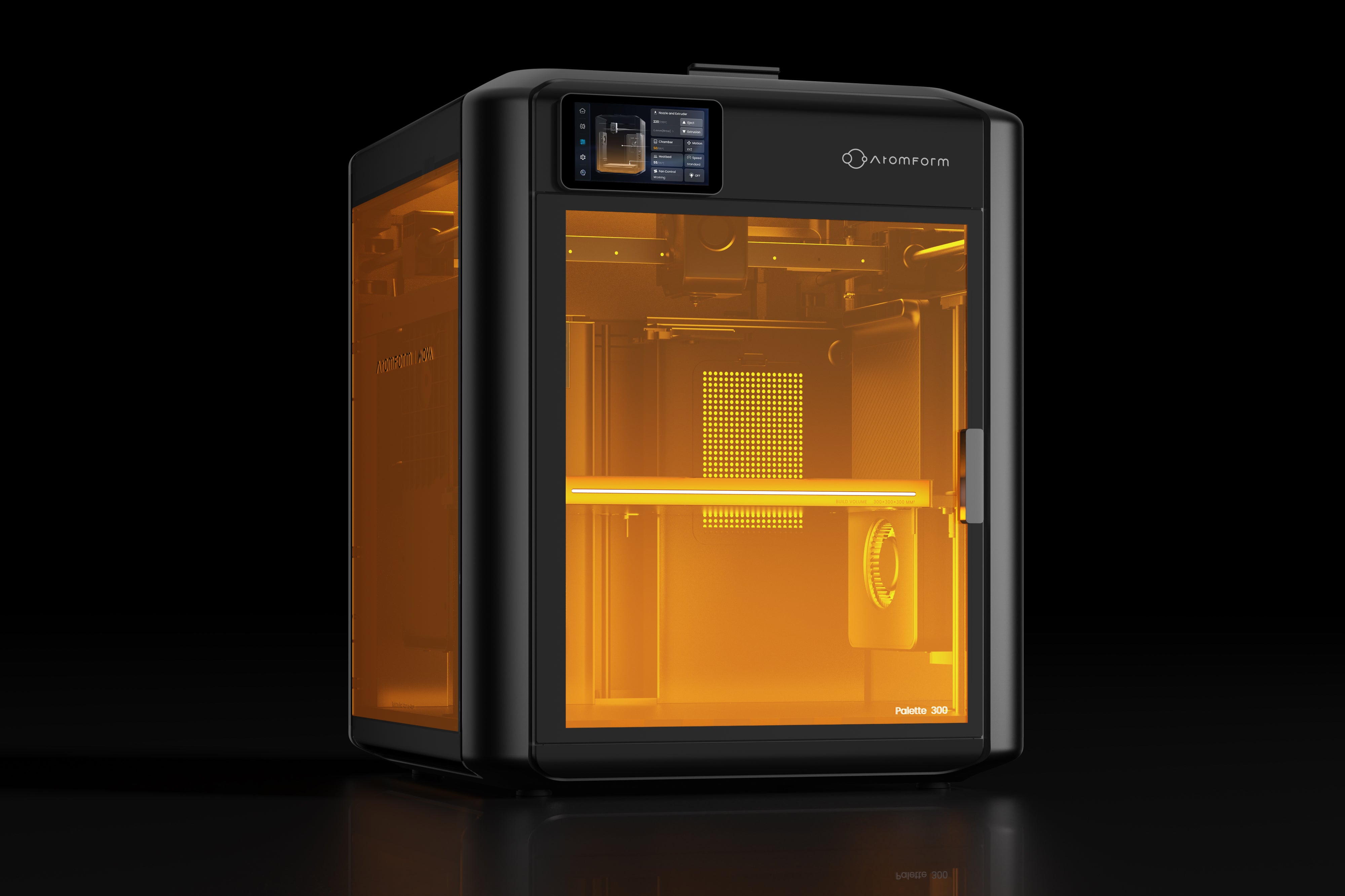

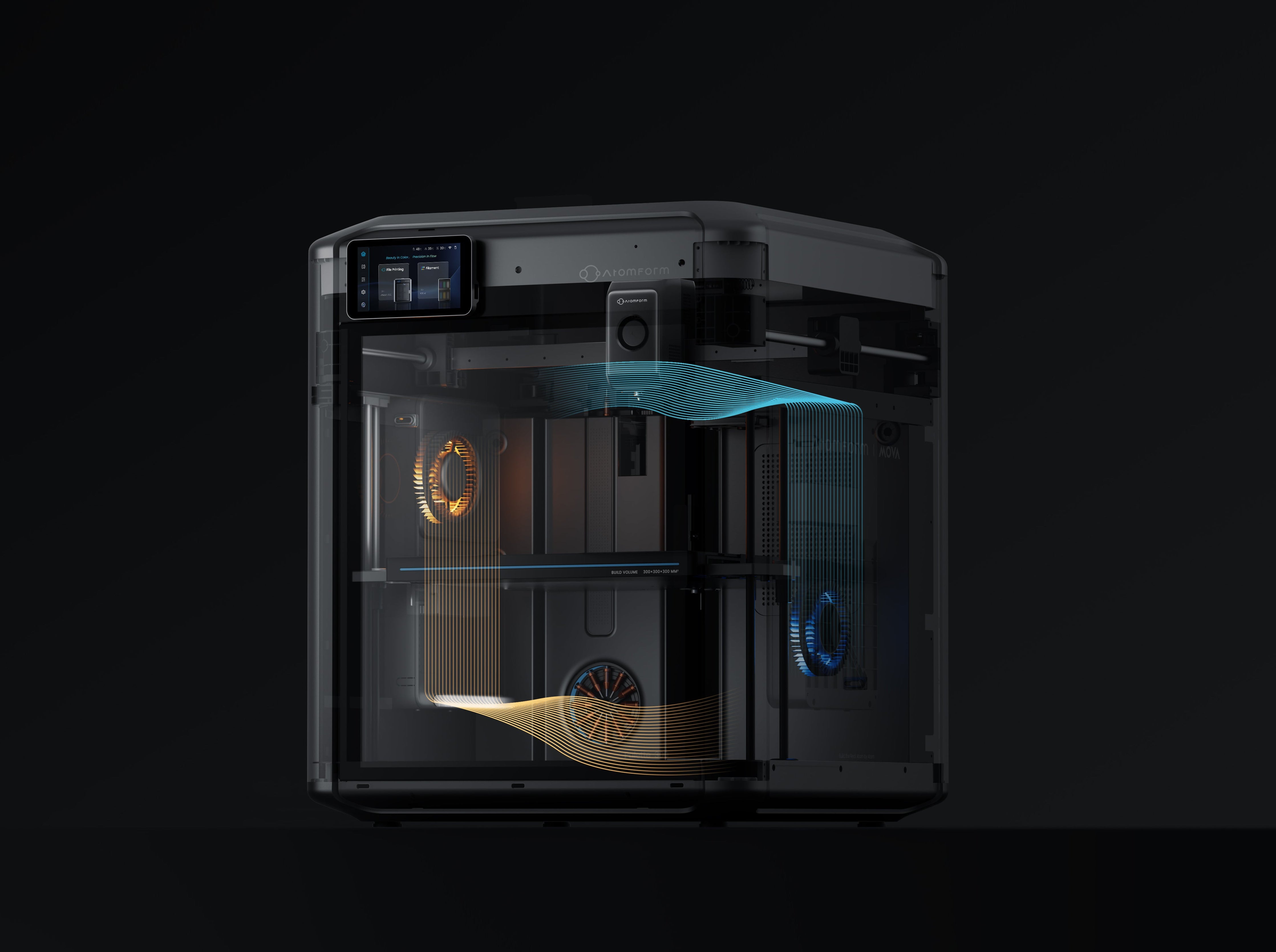

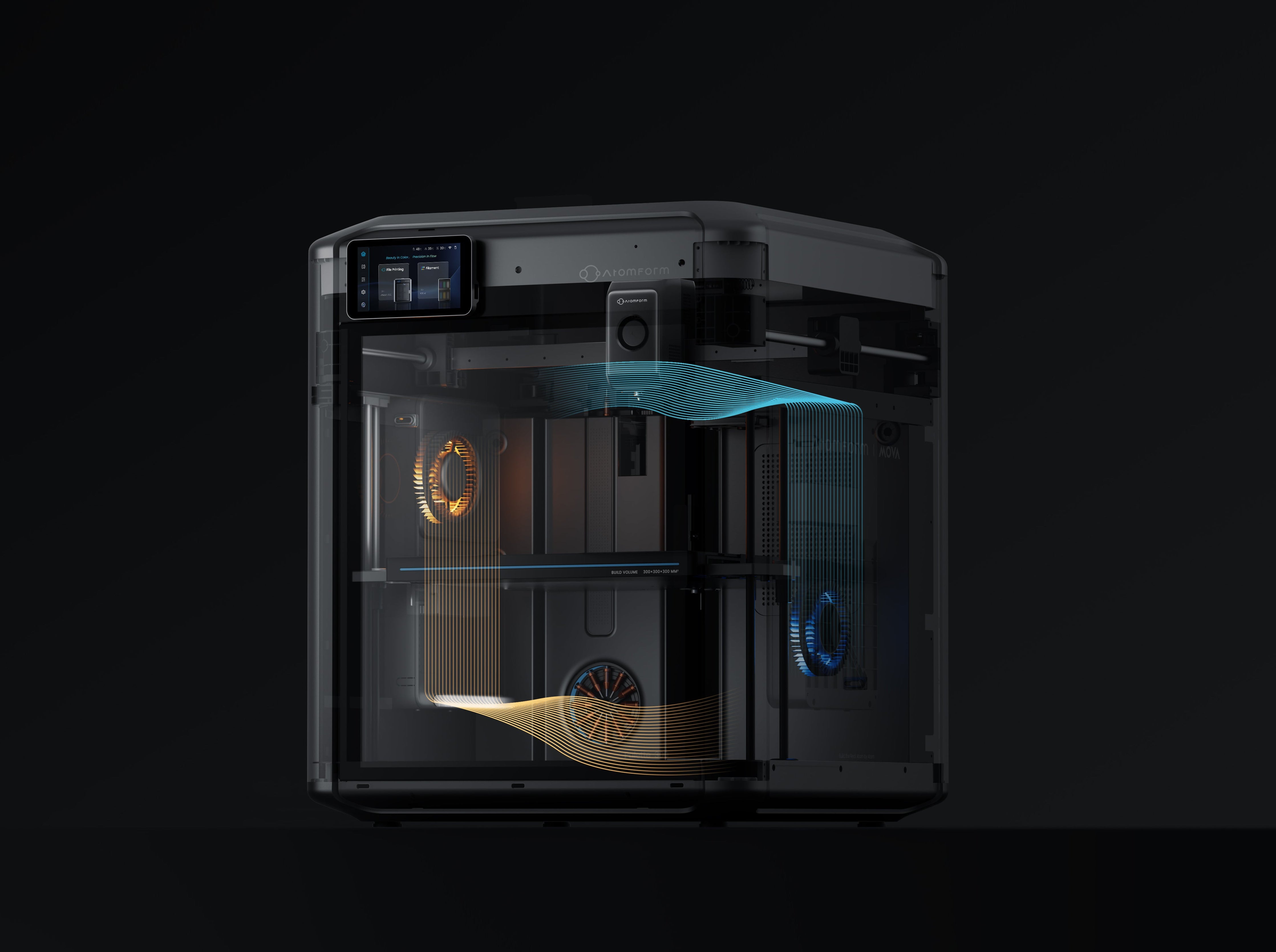

Multi-Color & Multi-Material

All in One Print

12

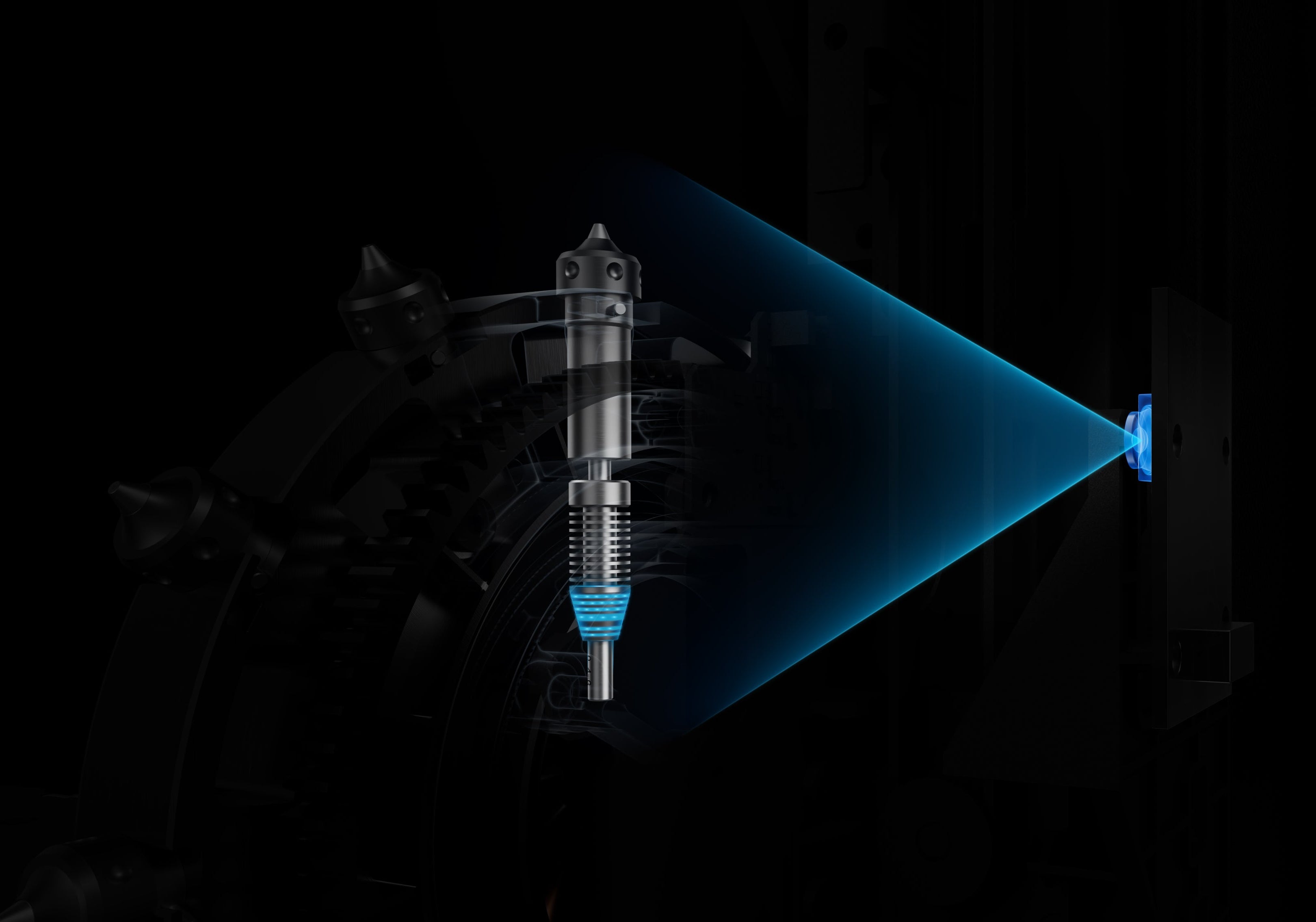

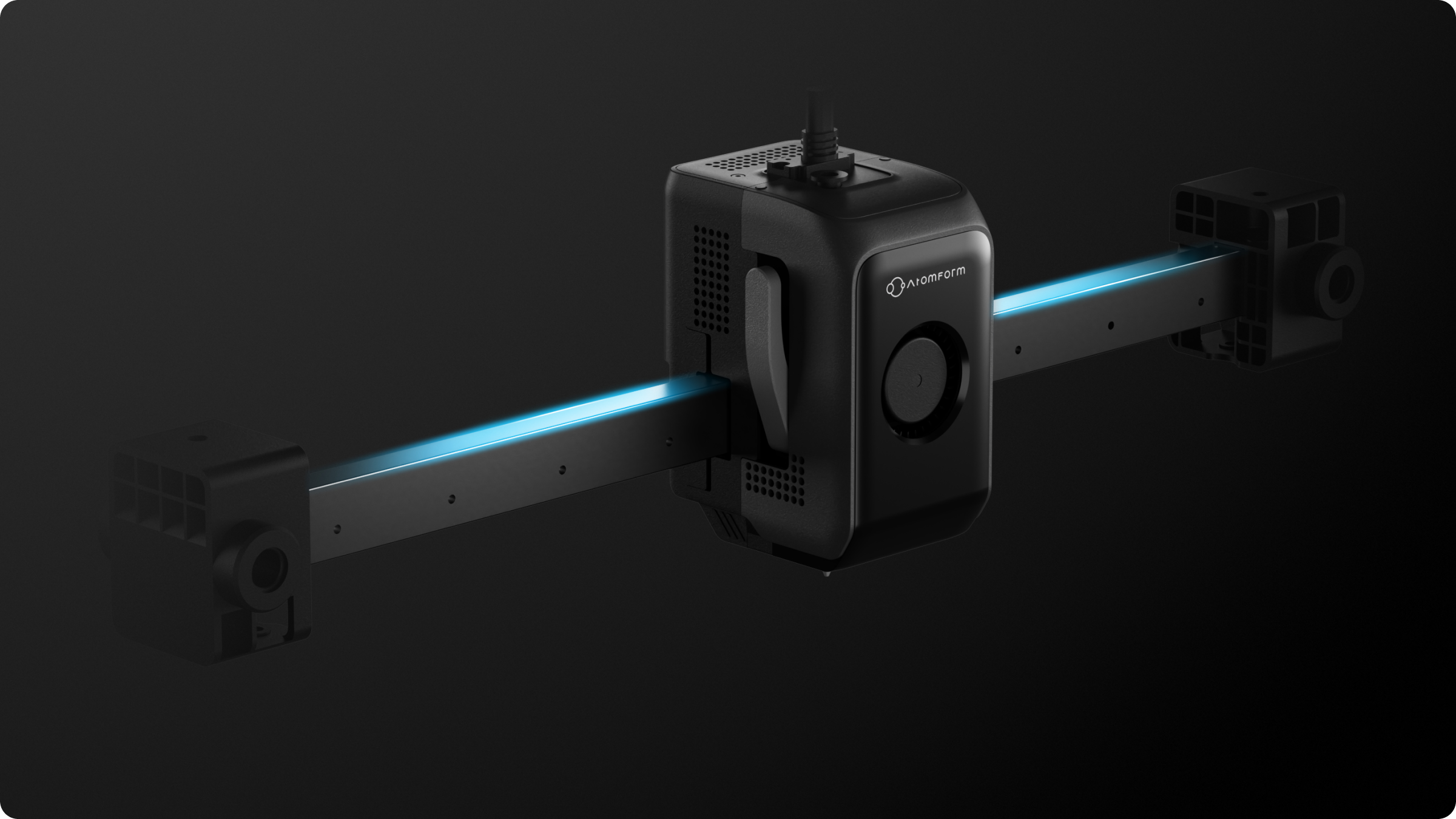

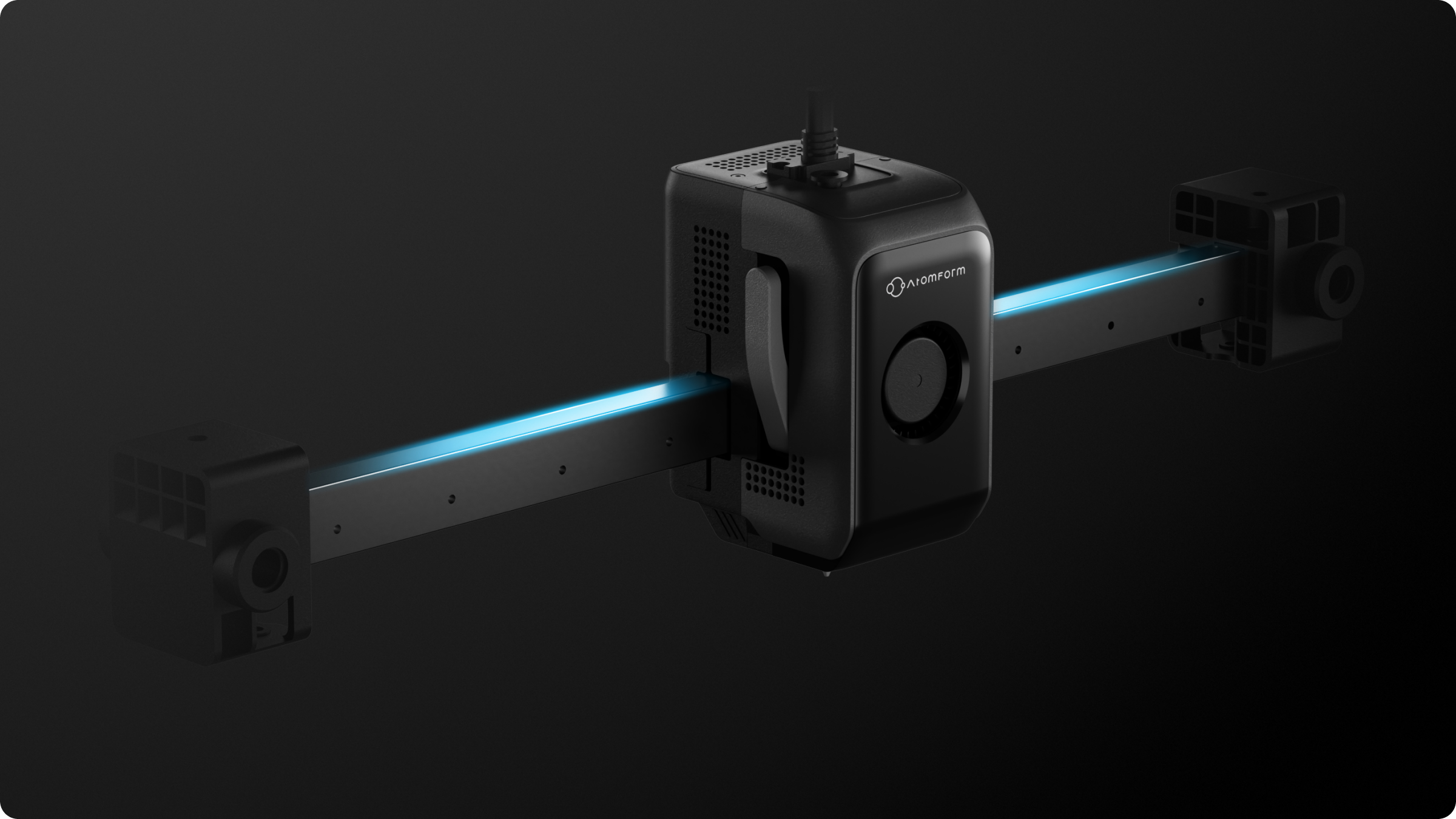

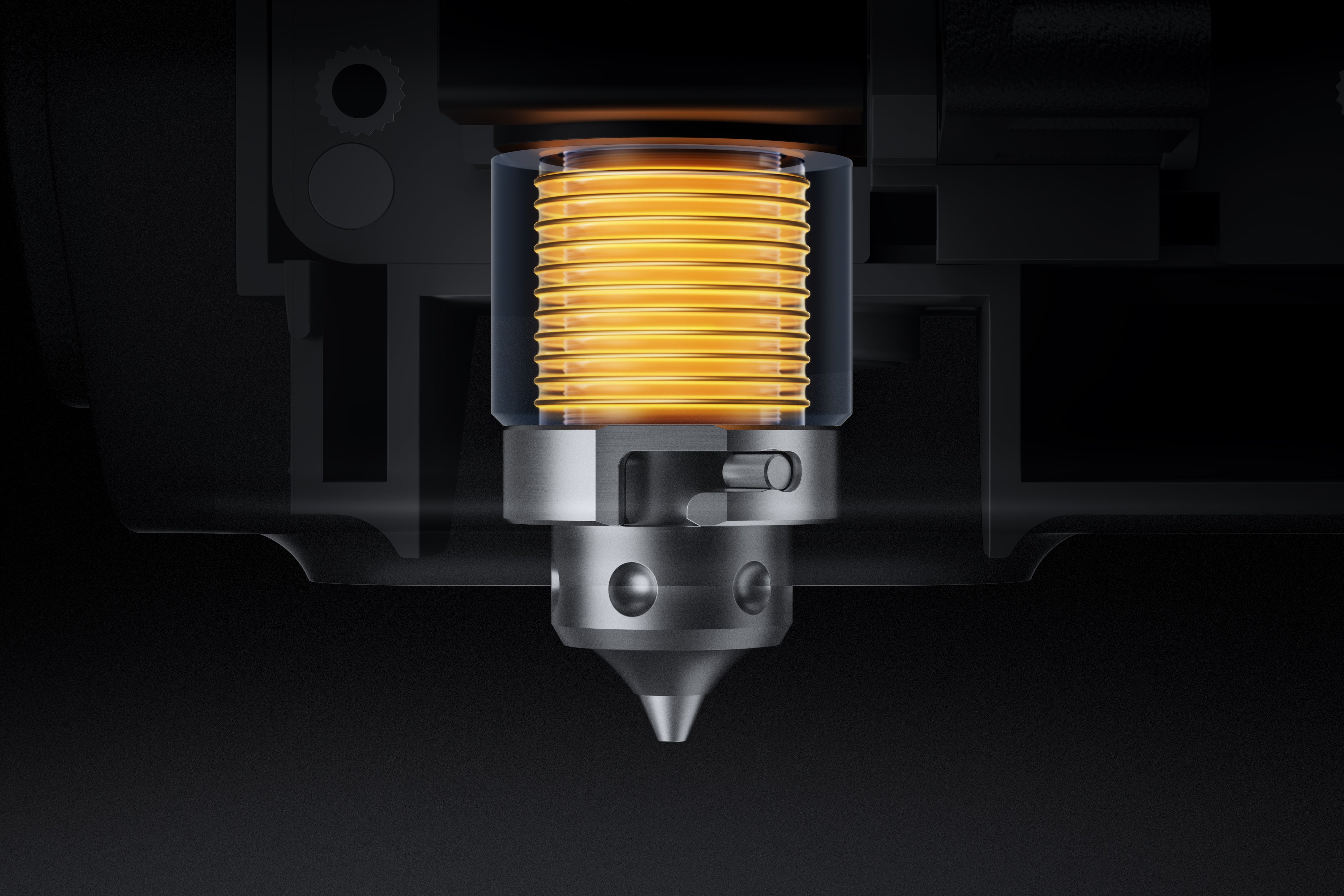

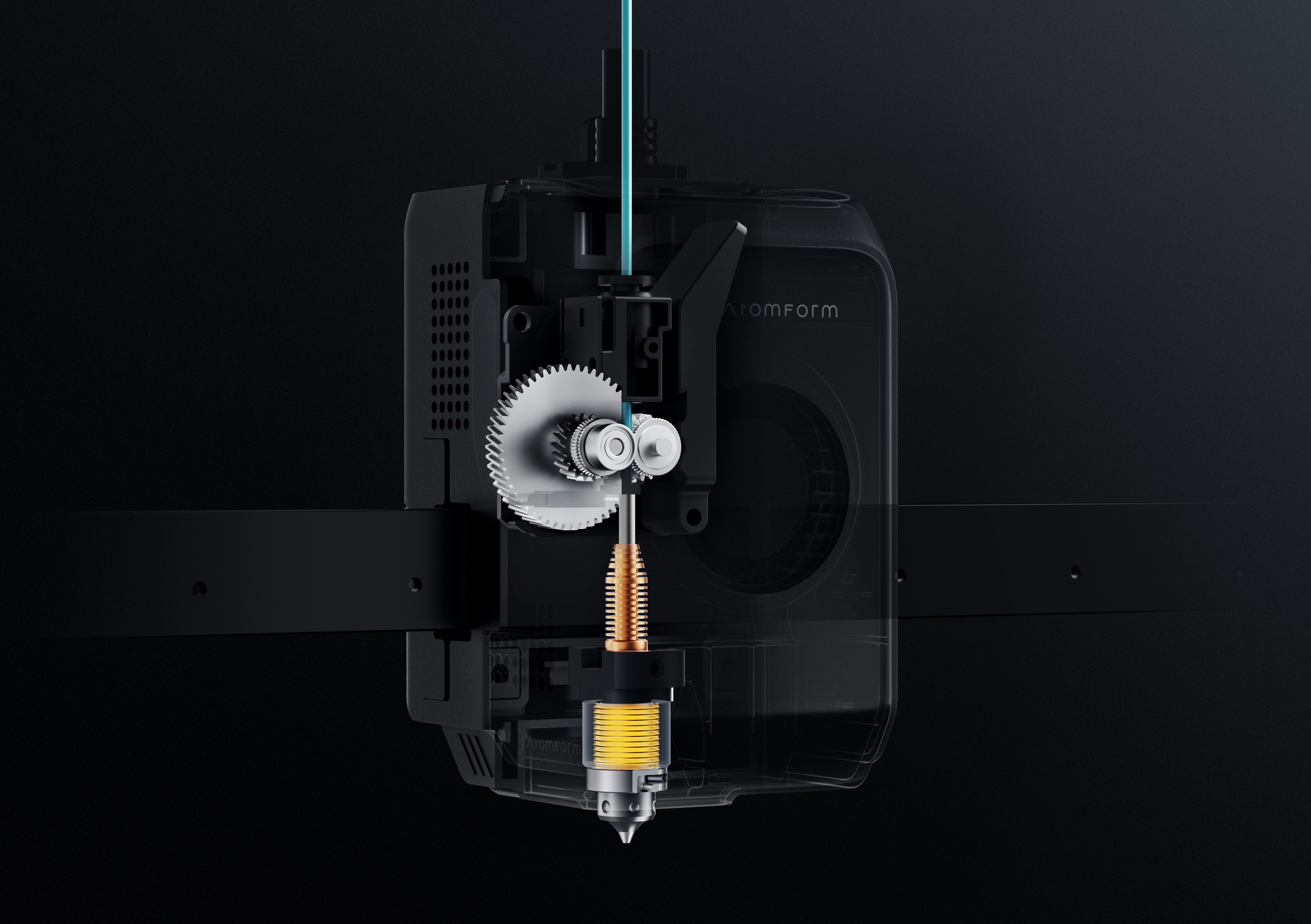

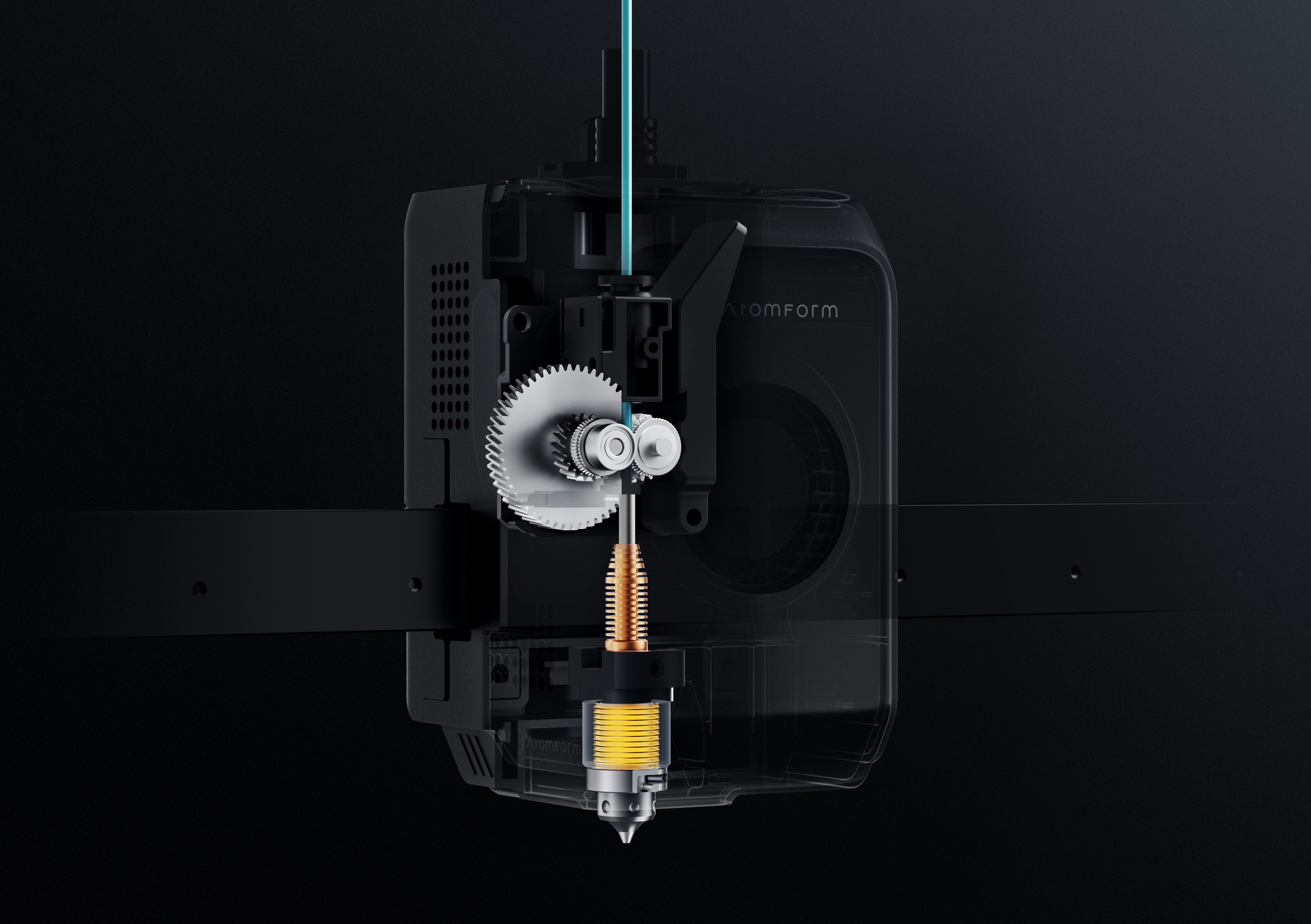

Auto-Swapping Nozzles

Faster and More Efficient for Multi-Material Printing

50%

Faster Swaps

[1]90%

Less Waste

[2]

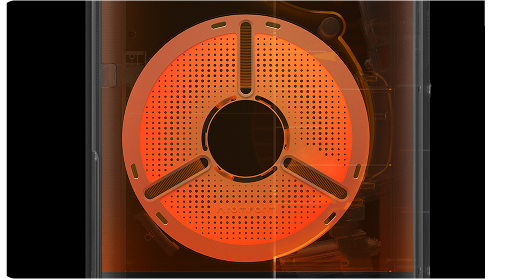

6 Spools

Built-in Drying

RFD-6: All-in-One Filament Solution

800mm/s

High Printing Speed

25000mm/s²

300×300×300mm

Large Volume

Every Switch. Art in Motion

12

90%

50%

Beyond Filament Management, Dryer Than Ever

One RFD-6 meets all your filament management needs. As an all-in-one system that integrates filament drying, storage, and feeding, one of its most innovative features is the dual-zone design. While the top section actively dries filament up to 85°C, the material in the bottom section can still be automatically fed for simultaneous printing*, making the workflow more efficient.

Drying

while Printing

Up to

85°C

Auto-Rotate

Drying

Temp & Humidity

Detection

Automated

Air Venting

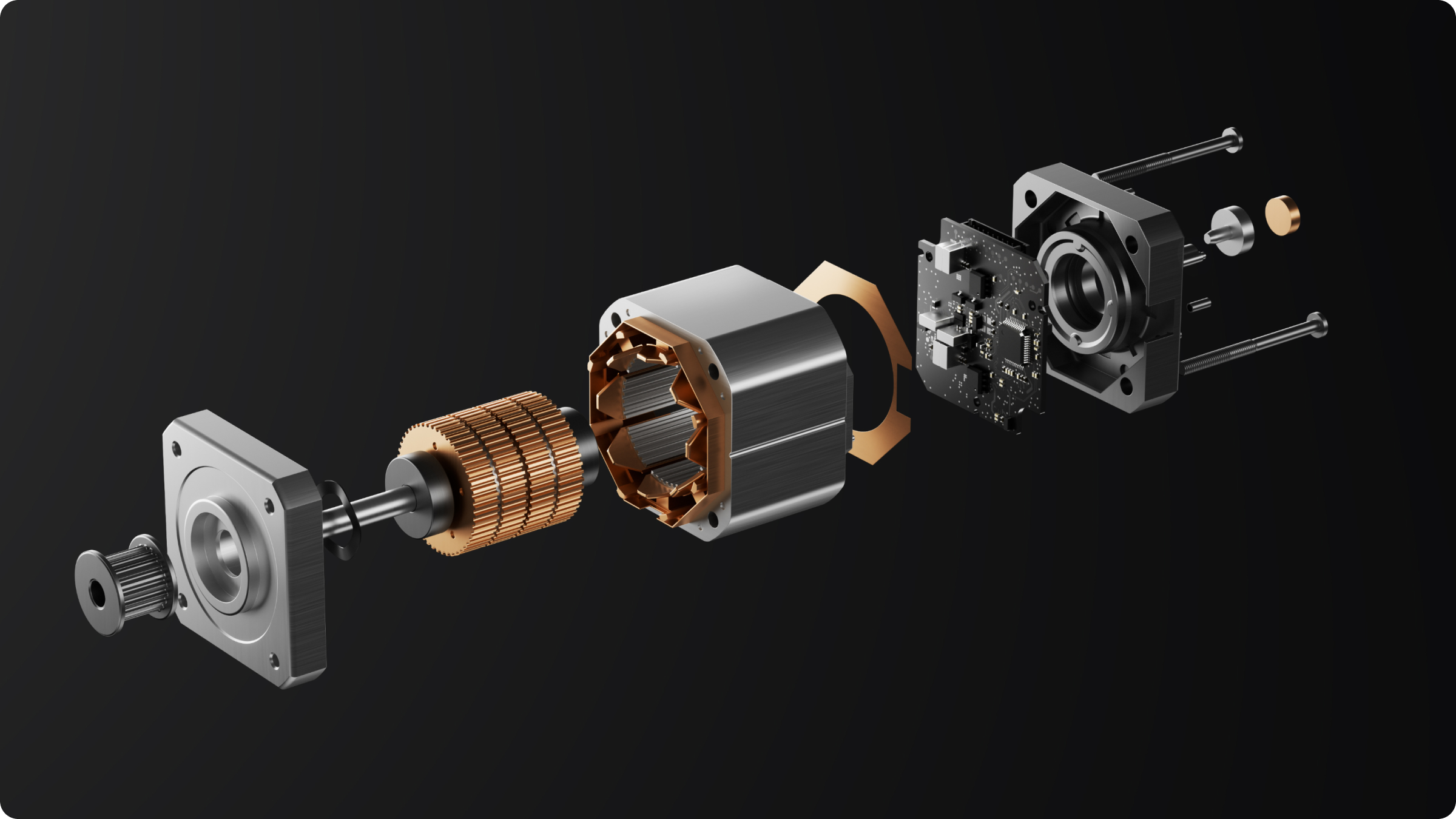

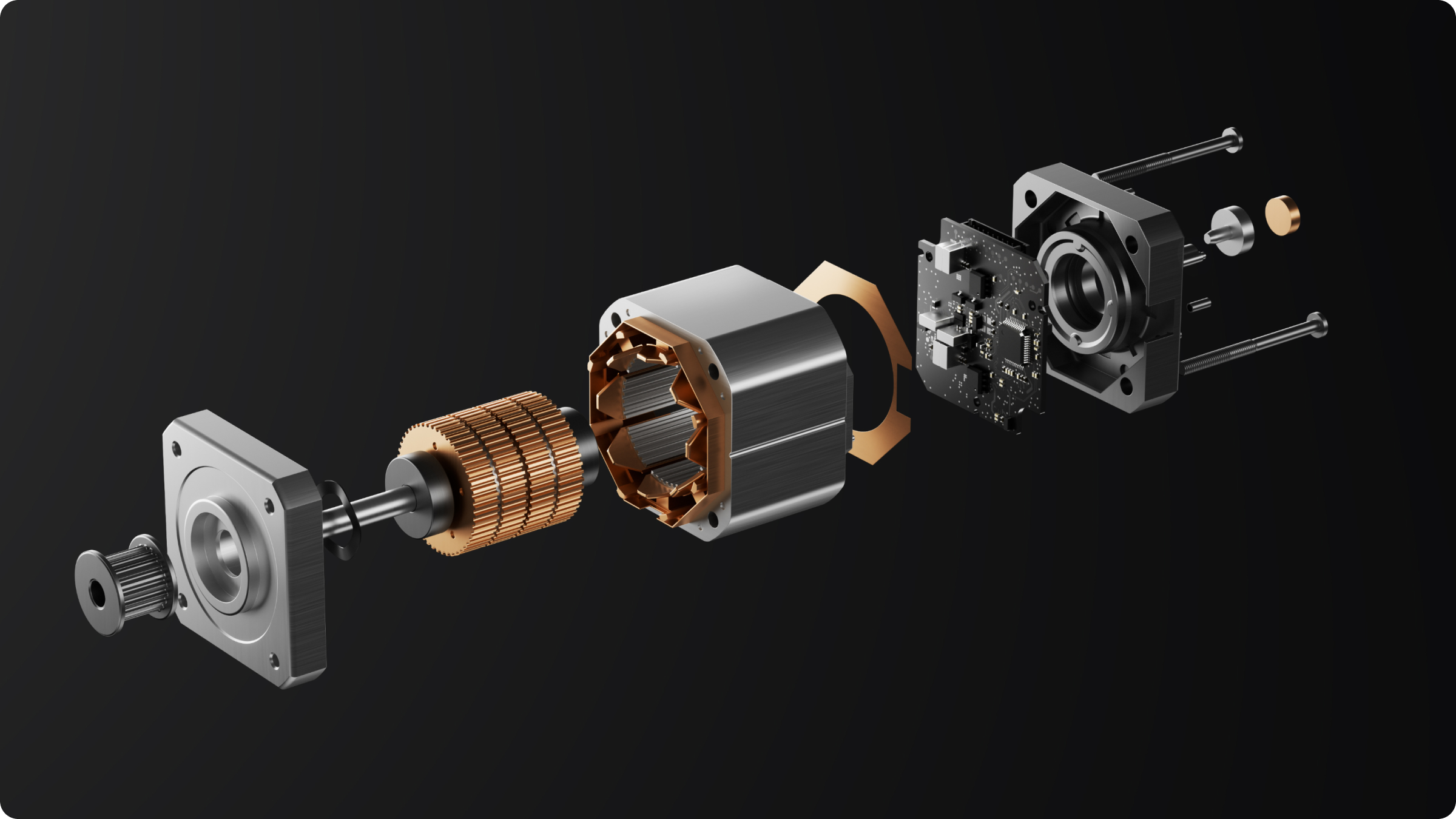

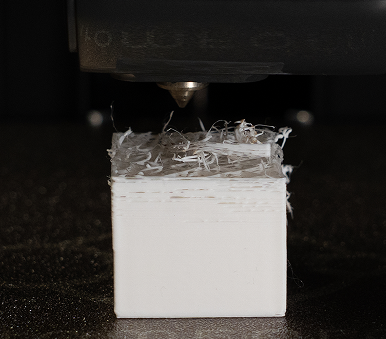

Twelve Nozzles Move as One

Automatically calculates and compensates for minute deviations in the nozzle center (dx,dy) in milliseconds, achieving an accuracy of up to ±0.02 mm.

[6]

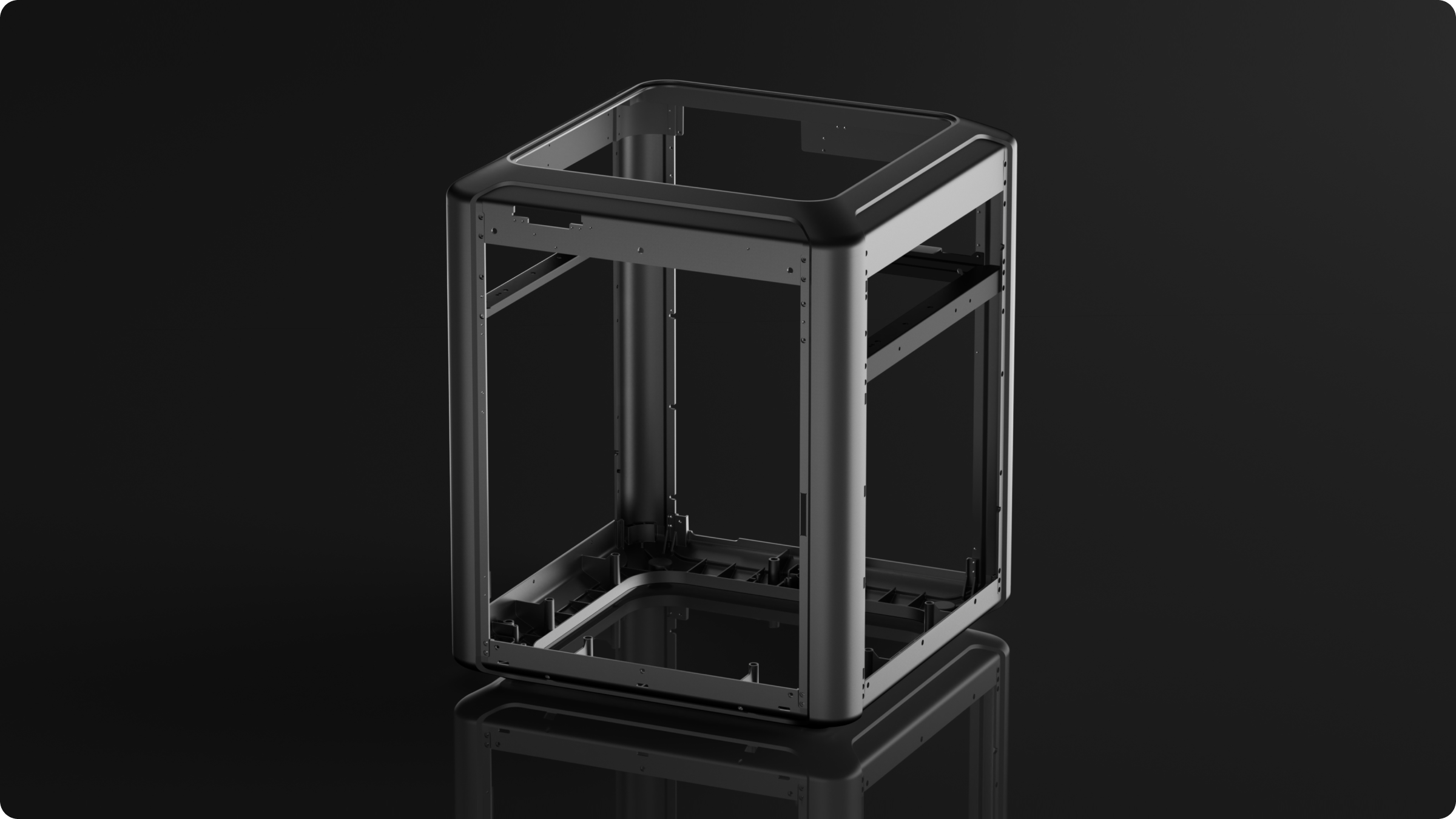

Engineered for

High-Speed Printing

From core drive to the whole chassis, Palette 300's stable system is engineered for speed without sacrificing precision.

Defining Extensive Material Compatibility

From everyday PLA and PETG to demanding engineering-grade filaments like PC and PPA.

Big Ideas, Formed in One Go

300 x 300 x 300 mm³ Build Volume

Full-Scale Prints

Print a complete large-scale, multi-color model in one go, no need to splitting it into multiple sections.

One-Go Production

Print an entire set of multi-material parts in one tray, boosting your production efficiency.

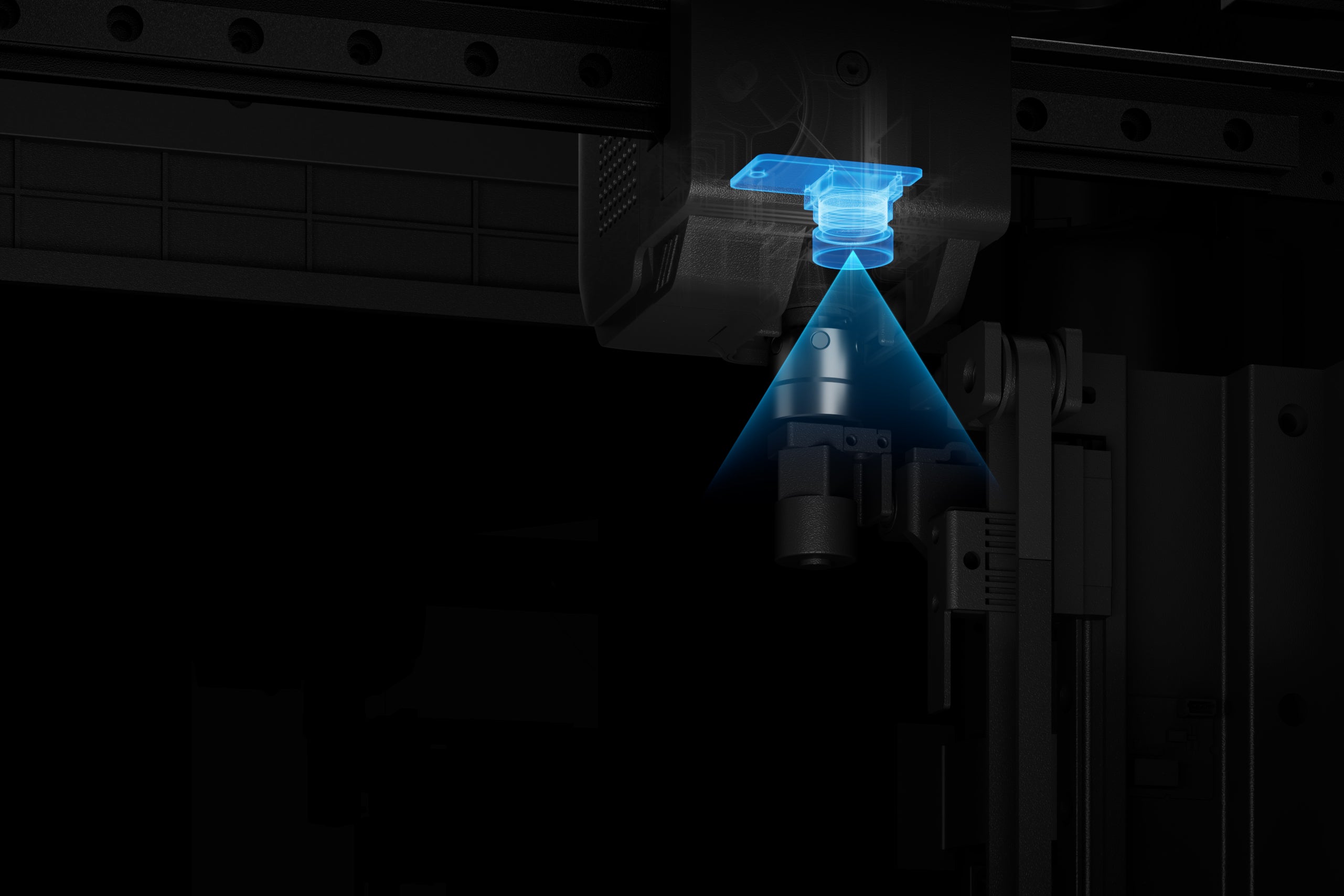

Start Precise. Print Perfect

Before every task, Palette 300 performs a comprehensive pre-print inspection, ensuring no foreign objects in the chamber and confirming the build plate's type is matched.

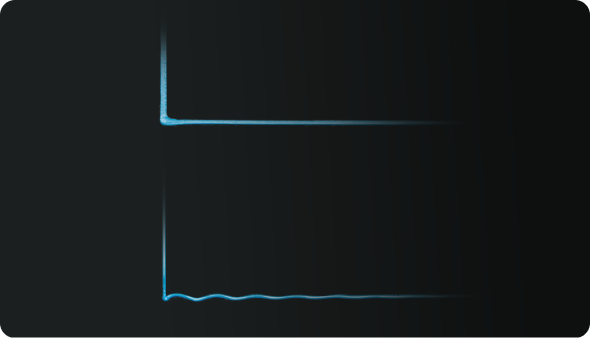

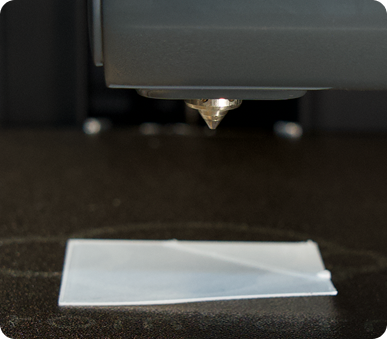

Active Auto-Leveling

Three independent Z-axis motors control the floating build plate, automatically leveling it to prevent print quality issues caused by a tilted print bed.

Active Vibration Compensation

Real-time micro-vibration compensation ensures stable, smooth quality even during high-speed printing.

PA Value Calibration

Measure nozzle pressure and calibrate the PA value to precisely control extrusion.

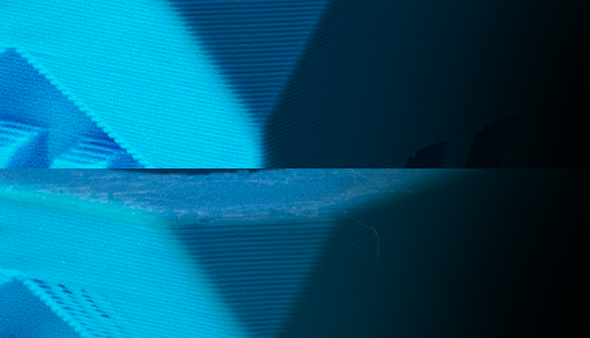

Real-Time Monitoring

All issues are instantly synced to the AtomForm APP, allowing you to monitor your print status anytime, anywhere, for truly worry-free remote management.

Nozzle Buildup

Warping

Spaghetti

Worry-Free, Inspired Creation

From unboxing to printing, hardware and software work seamlessly together, delivering a safe, clean, and quiet creative experience.

More Efficient Print Queue

Easily manage multiple projects without interrupting your current work. Simply add all tasks to the print queue at once.

Easier Device Management

Check the status of every printer from any page, without having to navigate to the specific device page.

Dual-activated Carbon and HEPA Filtration

Breathe easy. Our high-efficiency air filtration system actively removes harmful VOCs and PM2.5 particles, creating a healthier, safer environment for you and your projects.

≤48dB Operation[7]

Create in peace. The Palette 300's sound insulation design and low operating noise of just ≤48dB ensure your creative process remains undisturbed, so you can print with confidence at any time.

Privacy by Design[8]

Cameras are used to monitor prints only, ensuring your surrounding environment will never be captured.

Local Operation Option

Free to disable cloud services and maintain complete control over your data security.

50% Faster Swaps: This data applies only to a single color or material change.

90% Less Waste: This data applies only to a single color or material change.

The ReadyPrint™ instant feeding capability is realized only when the replacement filament is not located on the same feeding layer as the currently printing filament. When both filaments reside on the same feeding layer of the feeding system RFD-6, an additional feeding time is required for the filament loading.

This data was obtained by printing with PLA filament and a 0.4 mm standard-flow nozzle, using a 0.2 mm layer height, 200 mm/s outer wall speed, and 250 mm/s infill speed. ''Others'' refers to 3D printers that use a filament changer to swap materials.

Drying while Printing: Due to the differences in various material thermal stability, the simultaneous feeding of PLA and PETG is discouraged while the drying function is engaged.

This data was measured using clean nozzles. Calibrating with an unclean nozzle could lead to less accurate results.

This data was tested from AtomForm Lab using a certified decibel meter, measured at a distance of 1 meter from the machine in standby mode. The result ≤48 dB reflects the typical average operational noise level.

To protect user privacy, the camera's physical viewing angle is restricted to prevent capturing the surrounding environment outside the printer enclosure.